Emergency lighting for industrial buildings and warehousing is essential, activating when the mains power supply to the normal lighting fails.

Emergency lighting is critical for maintaining safety standards in these working environments, particularly concerning fire safety. Fire safety has become a major public concern in the wake of the Grenfell disaster, leading to tighter compliance standards across all building types.

In this article, we explore the role of emergency lighting, the compliance landscape, and its key components, as well as best practices in industrial settings.

The Importance of Emergency Lighting

There are three key reasons why emergency lighting is crucial:

- Building safety. In the event of a power outage or emergency, employees must evacuate the premises quickly and safely. Emergency lighting illuminates pathways, exit routes, staircases, and emergency exits, helping to reduce panic and prevent injuries.

- Mitigating risk. For many industrial operations, a sudden blackout can disrupt critical processes. Emergency lighting allows for a controlled shutdown of machinery, preventing potential hazards.

- Compliance. Adhering to emergency lighting standards is mandatory under various building codes and standards, as we explore in more detail below. Non-compliance can result in significant fines and, more importantly, jeopardise employee safety.

Emergency Lighting Standards and Building Regulations

According to the Industry Committee for Emergency Lighting (ICEL), ‘The legal requirement is that non-domestic buildings must be safe at all times, even if mains power failure occurs. Therefore, nearly all such buildings must have emergency lighting fitted’.

The ICEL is the UK’s authority on emergency lighting, providing third-party accreditation for emergency light fitting components and products under the guidance of the Lighting Industry Association (LIA).

Key legislation and standards to be aware of include:

- The Regulatory Reform (Fire Safety) Order 2005 (FSO) is the primary legislation governing fire safety in non-domestic properties in the UK. It requires any person who exercises some level of control for premises (the ‘responsible person’) to take reasonable steps to reduce the risk from fire and ensure that people can escape safely if a fire does occur.

- The British Standards Institution (BSI)’s BS 5266-1 is the code of practice for the emergency lighting of premises. The Fire Industry Association’s guide offers more detailed requirements for emergency lighting regulations in the UK.

- The British and European standard, BS EN 1838 details the two main types of emergency lighting; emergency escape lighting and standby lighting.

- By law, all ‘life safety systems’ must be supported by a continuous emergency power source, and emergency lighting must have at least three hours of backup power. Many facilities opt to include both an uninterrupted power supply (UPS) system and a central battery system (CBS) to achieve a secondary emergency power supply.

Key Components of Emergency Lighting Systems

An effective emergency lighting system for an industrial facility typically includes the following components:

- Emergency exit signs. Illuminated signs that indicate the location of exits. These are essential for guiding occupants out of the building safely.

- Standby lighting. Provides enough illumination for normal activities to continue if the main lighting fails. In industrial settings, this is crucial for maintaining safety and security.

- Escape route lighting. Ensures that all pathways leading to the exit are well-lit, reducing the risk of trips and falls during an evacuation.

- Open area lighting (anti-panic lighting). Prevents panic in open areas by providing sufficient lighting for people to move towards escape routes calmly.

- High-risk task area lighting. Specific lighting for areas where dangerous tasks are performed, ensuring these areas remain illuminated to prevent accidents during a power outage.

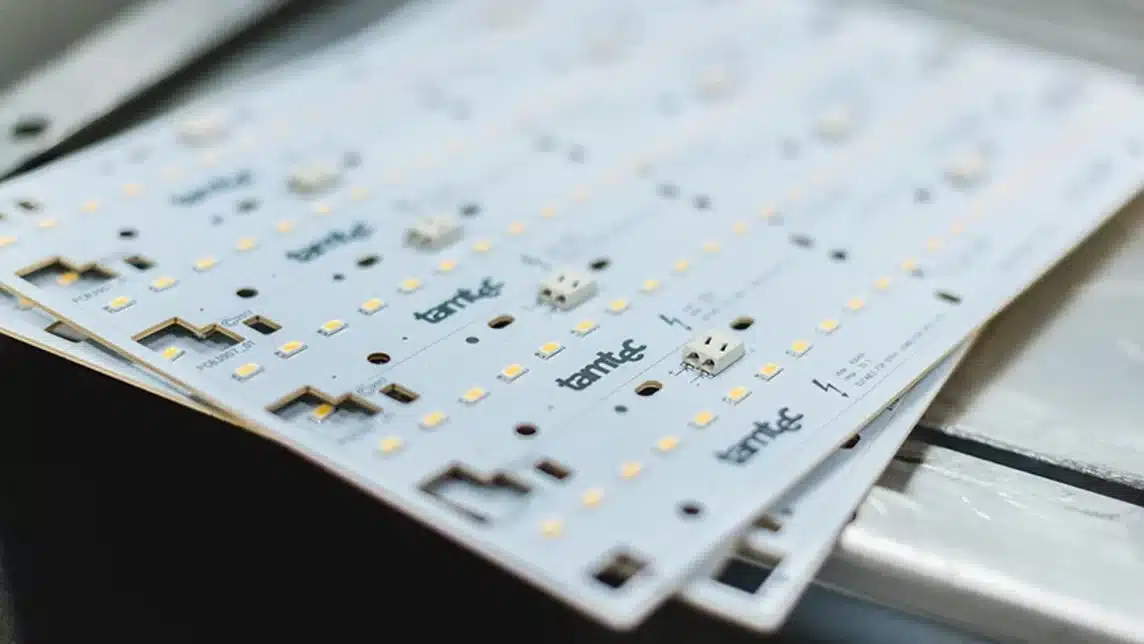

- LED-based lighting system. According to the Energy Saving Trust, LEDs consume up to 80% less energy than traditional incandescent lamps. This makes LEDs more energy efficient, particularly in large industrial buildings where cost savings can be significant. Furthermore, LED systems result in fewer carbon emissions.

Best Practices for Implementation

To maximise the effectiveness of your emergency lighting system, consider the following best practices:

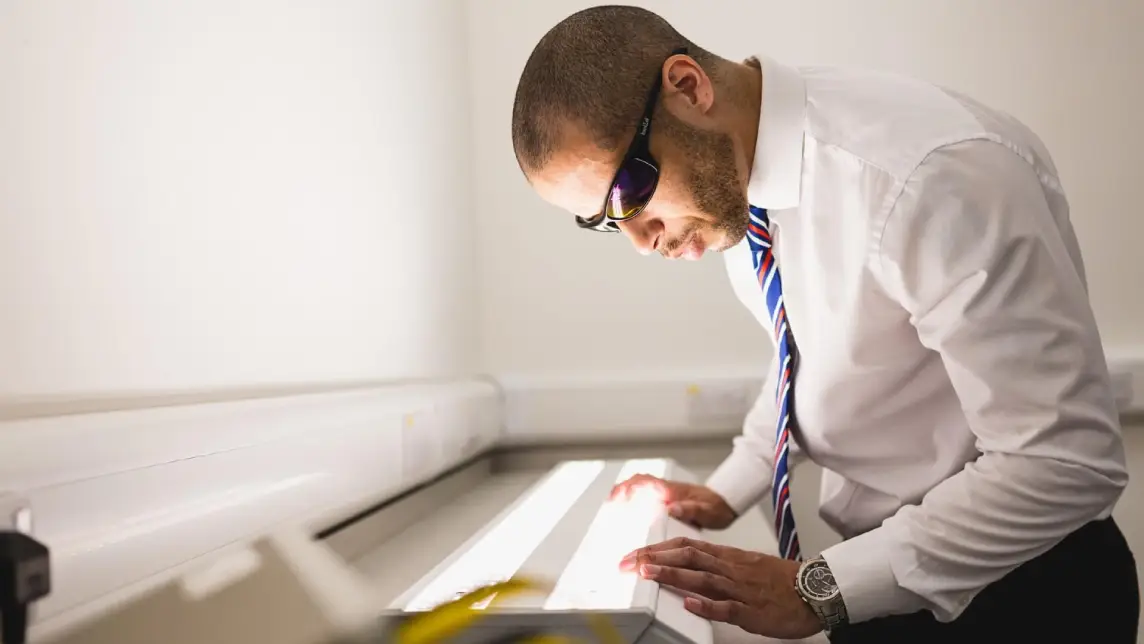

- Regular maintenance and testing. Perform regular inspections and tests of all emergency lighting components to ensure they are functioning correctly. This might include monthly functional tests and annual full discharge tests.

- Proper placement. Strategically place emergency lights and exit signs to cover all potential exit routes, open areas, and high-risk task zones. Ensure there are no obstructions that could block the exit signs or emergency light.

- Employee training. Employees need to be familiar with the location and use of emergency exits and the importance of emergency lighting. Conduct regular evacuation drills to reinforce this knowledge.

- Stay updated. Keep abreast of updates to compliance standards and building codes. Regularly review and update your emergency lighting systems to meet any new requirements (see information about Tamlite’s FREE CIBSE Approved CPD Module ‘Emergency Lighting’ below).

Emergency lighting in industrial buildings and warehouses is a critical aspect of workplace and building safety. By understanding its importance, adhering to standards, and following best practices, you can ensure that your facility is well-prepared to handle emergencies, safeguarding both your employees and your operations.

- Tamlite’s FREE CIBSE Approved CPD Module ‘Emergency Lighting’ is designed to support lighting designers, architects, consultants, electrical contractors, FMs, and building managers. The module covers the latest guidance, regulations, and technological solutions to ensure emergency lighting compliance. Click here for more information or to book your session.